3D Printing

.jpg)

We have been talking a lot in the Headjam studio about purchasing a 3D printer. Trying to determine which unit is the right choice for the scale of projects we want to do. Is the technology advanced to the right stage to make the investment? If we wait another year will CLIP technology be available? Will that change everything? We ummed and ahhhed and got pretty close at one stage to committing to a kick starter project that was looking at creating a 3D printer that used interchangeable heads to turn into a router or laser cutter. However — there were doubts in a few of the Headjammers minds about whether the technology was there yet. Was it still in the fad stage?

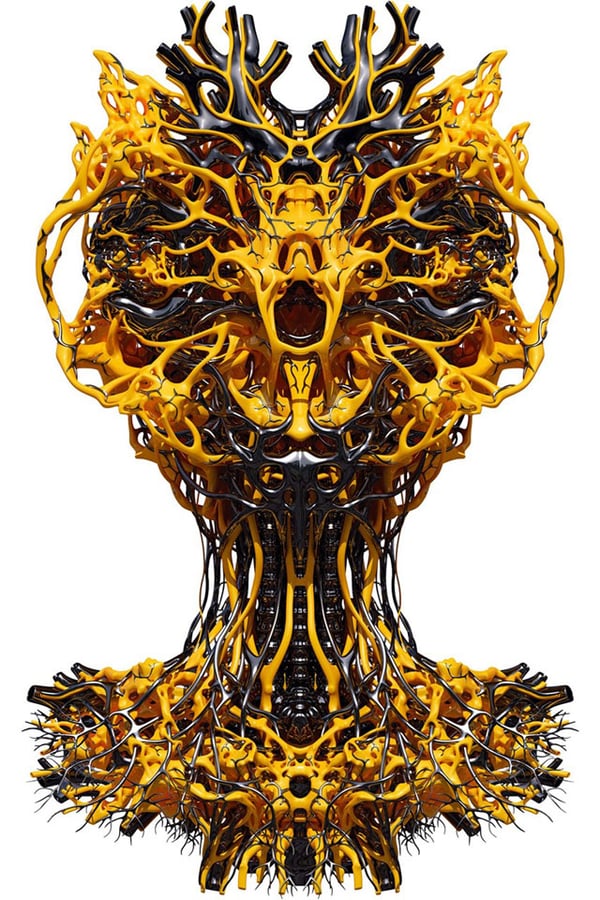

See image here.

I first used 3D printing in 2009. In Australia it was fairly new technology. Our University was pretty chuffed to have one. I designed a biodegradable water bottle for my final project and was able to use the printer to create a prototype of the design. It look over two days to print and I went and “visited” the bottle as it came to life. It was created using resin which hardens as it is printed and the layers build up as it is “printed”. It really is 2D printing that is layer upon layer. This method is refereed to as additive manufacturing.

See image here.

3D modeling software is readily available, some suppliers such as Tinkercad even offering in browser options. This software is used to create a 3D model of the object that is to be printed. To produce a 3D printed object a printer then uses the STL (sterolithorgraphy) file to create the layers which in turn create a 3D form. 3D software creates these slices of information that is fed to the printer to produce.

CLIP technology, as I mentioned earlier, is the move advance versions of 3D printing being currently tested. It uses a combination of Light and Oxygen to create a chemical reaction. UV light triggers photopolymerization and oxygen prevents it. By balancing the interaction of light and oxygen, CLIP continuously grows objects from a pool of resin. It is quite spectacular to watch. Unfortunately this technology isn’t yet available. However, the traditional methods of 3D printing are also advancing rapidly. The Ultimaker 2 is a state-of-the-art desktop version of a 3D printer. Using Octoprint or Cura software the Ultimaker can read these slices of information and print at a resolution of 20 microns. Also known as: freakin amazing.

See image here.

This type of printing still faces issues, open air, or unsupported printing is when the printer is printing a piece that extends back down, imagine an arm, you often get little squiggle of material that haven’t been able to connect or set in time. These are easily cleaned off, however it is an interesting thought.

As the abilities of 3D printers increases, the uses become more and more exciting. Being able to send a STL file to the other side of the world to have it printed by the time someone arrives at work. In the medical world the uses are even more exciting. In 2014, a five-year-old girl became the first child to have a prosthetic hand made with 3D printing technology. Her hand was designed by E-nable, an open source design organisation which make prosthetics mainly for children. The prosthetic hand was based on a plaster cast made by her parents.

See image here.

At Headjam we are constantly looking to provide innovative solutions for our clients’ challenges. Providing 3D printing options for clients allows us to explore forms and outcomes that previously would only be possible with expensive manufacturing methods. Get in touch to discuss how 3D printing and Headjam can help you express your ideas.